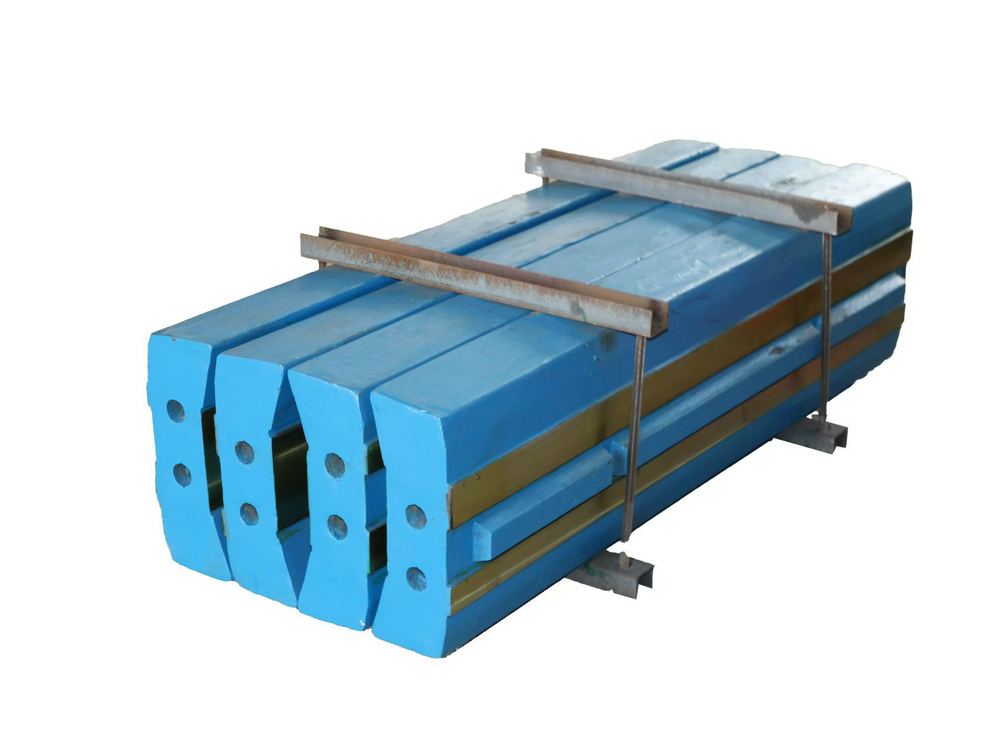

Plate hammer is an important part of crusher, and because of its particularity, it needs to have relatively good wear resistance. So what does the wear resistance of the plate hammer depend on? That is the casting process for producing plate hammers.

When casting a plate hammer, the process is complicated and there are many links. The wear resistance is also affected by various factors, however, among these factors, casting technology occupies a large part. Therefore, in the process of producing plate hammer, the production process should be designed reasonably first. This link is very important, which is related to the quality of the plate hammer. If there are defects in the interior or surface of the plate hammer, it can't help us solve the problem when we use it. It may also increase the release rate of accidents, so we should ensure the casting process of the plate hammer.

For example, take a plate hammer made of high chromium cast iron. Reasonable use of external cooling iron and vertical watering and strict control of pouring temperature can effectively ensure the advantages of plate hammer in internal organization. Due to the heat treatment process of the hammer head, the physical form of the plate hammer is directly solved. Making full use of hot and cold attention can make the plate hammer in a stable state. This is a problem that all manufacturers of plate hammers should consider. Through the above contents provided by Zhiteng high chromium plate hammer manufacturer, if you want to produce a plate hammer with good quality, you must pay attention to its casting process. Therefore, I would like to remind everyone to choose carefully when buying the plate hammer, and I hope everyone can choose the plate hammer with the right quality.

Loudi Zhiteng New Material Co., Ltd. is a casting enterprise of wear-resistant parts; Mainly engaged in grinding mortar wall broken wall, jaw plate, hammer head, plate hammer, ball mill liner and other wear-resistant accessories; There are medium, high and ultra-high manganese steel, wear-resistant alloy steel and low, medium and high chromium cast iron materials. Mainly for mining, cement, building materials, electric power, gravel plant, machinery manufacturing and other industries to produce and supply wear-resistant castings; A production base of mining machine parts with an annual production capacity of more than 10,000 tons.

In fact, the plate hammer is the main striking element of the impact crusher, so many people call it the plate hammer crusher. The working principle, operating model, advantages and disadvantages of the plate hammer crusher will be counted one by one to deepen your understanding of the plate hammer crusher. Working principle of plate hammer crusher

The crushing power belongs to impact energy. When the motor is started, the rotor rotates at high speed, and the material enters the crushing cavity through the conveyor, then collides with the plate hammer on the rotor through the plate hammer crushing area, and then is thrown to the impact device to be crushed again, and then bounces back to the plate hammer action area from the impact liner to be crushed again, and so on. The material enters the first, second and third impact cavities respectively according to the particle size and is repeatedly crushed until it is crushed to the expected particle size, and is discharged from the discharge port. Operation advantages of plate hammer crusher

(1) impact working principle, ore is broken along the joint surface, which reduces power consumption and has high discharging efficiency;

(2) the crushing ratio can reach 40, which simplifies the crushing process, simplifies the three-stage crushing into two-stage or single-stage crushing, and reduces the configuration cost of crushing equipment;

(3) The discharging specification of the plate hammer crusher can be adjusted, and the discharging particle type and granularity can be adjusted by adjusting the gap between the impact frame and the rotor;

④ The material of the plate hammer is upgraded to high chromium, which is impact-resistant, more wear-resistant and has greater impact force;

⑤ Keyless connection makes maintenance more economical and convenient;

⑥ It has selective crushing function, and the crushed products are uniform in particle size and mostly cubic stones in shape, which can meet the material requirements of high-standard infrastructure projects.

What are the shortcomings of the plate hammer crusher?

There are also shortcomings in the work of the plate hammer crusher, that is, the plate hammer is very easy to wear, especially when processing high-hardness materials, and the wear is more serious, so it needs to be replaced frequently. Therefore, the use of the plate hammer crusher is limited in the range of high-hardness materials, and it is more commonly used for materials with medium hardness and below. However, with the continuous emergence of wear-resistant materials, the shortcoming of plate hammer crusher is gradually improving, and it is currently applied in a small number of metal mineral processing production lines.