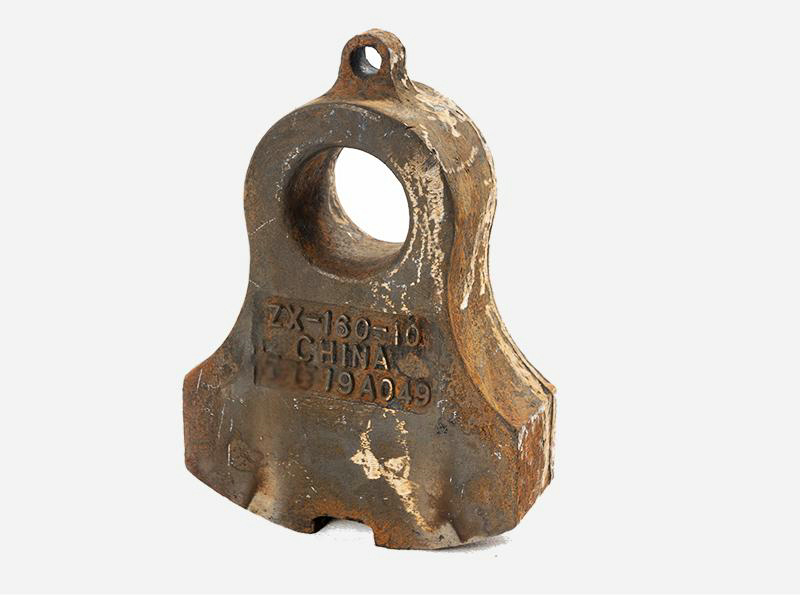

Four types of crusher hammers in common use

1, forging hammer

Forging hammer is a processing method that the metal is heated to the temperature of 700-1300℃, and then the metal blank is pressed by forging machinery to make it plastically deformed to obtain forgings with certain mechanical properties, shapes and sizes. Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metal during smelting. The mechanical properties of forgings are generally better than those of castings of the same material.

2, high manganese steel hammer

High manganese steel hammer has high toughness, good manufacturability and low price. When the hammer is subjected to large impact or contact stress, the surface layer of the hammer will rapidly produce work hardening, and its work hardening index is about 6 times higher than that of other materials, thus greatly improving the wear resistance.

3. Composite hammer head

The so-called composite hammer, also called alloy hammer, is to combine two kinds of metals suitable for making crusher hammers, usually high manganese steel and high chromium alloy. These two materials have the advantages of toughness and wear resistance, and they can give full play to their characteristics when combined. There are also multi-metal alloy hammers, and the performance is further improved. Most heavy hammer crushers use this kind of hammer.

4, inlaid alloy bar hammer

The hammer head of this crusher uses high-quality reinforced ultra-high manganese steel as the base material of the hammer head, and ultra-hard tungsten-titanium alloy as the main wear material, that is, wear-resistant alloy blocks are embedded in the hammer body of the high manganese steel. The hammer not only inherits the advantages of high toughness, high reliability and good wear resistance of the original high-quality reinforced ultra-high manganese steel, but also has the wear resistance of ultra-hard tungsten-titanium alloy. But the disadvantage is that the price is high, the production process is strict, and the stability is difficult to guarantee!